Why Rethink?

Existing Methods Left Managers With Too Many Questions

So We Acted.

Our “Game-Changing” Solution

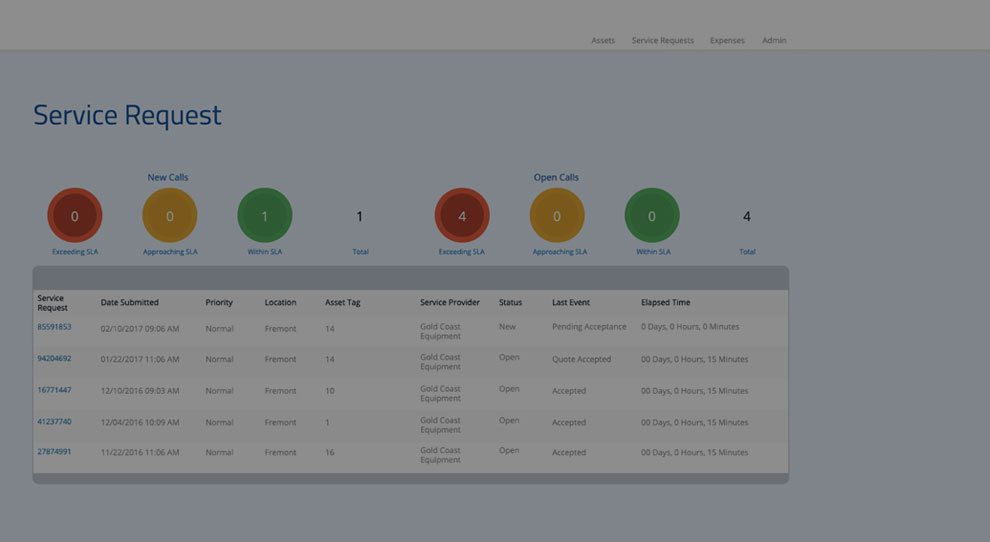

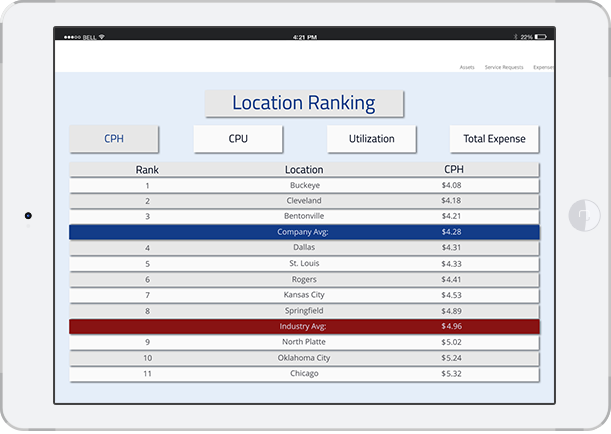

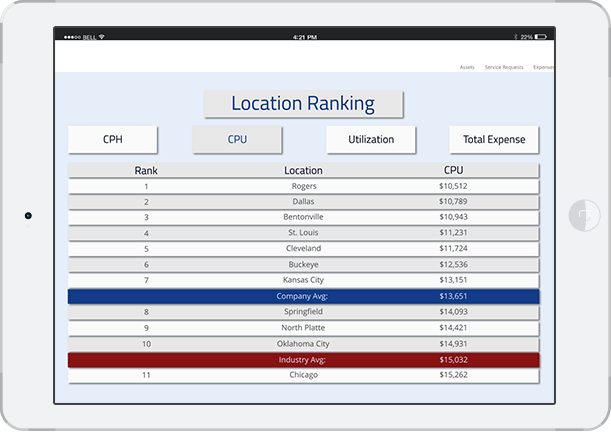

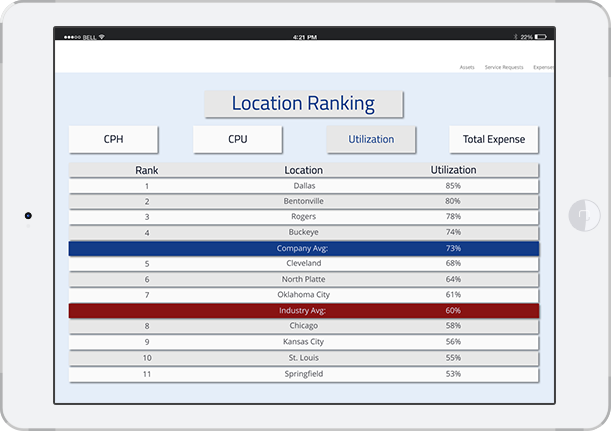

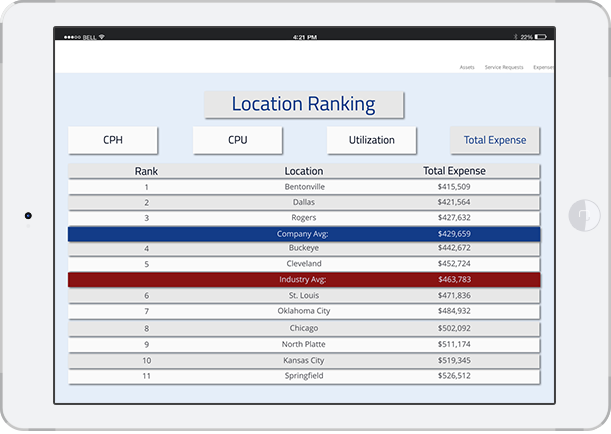

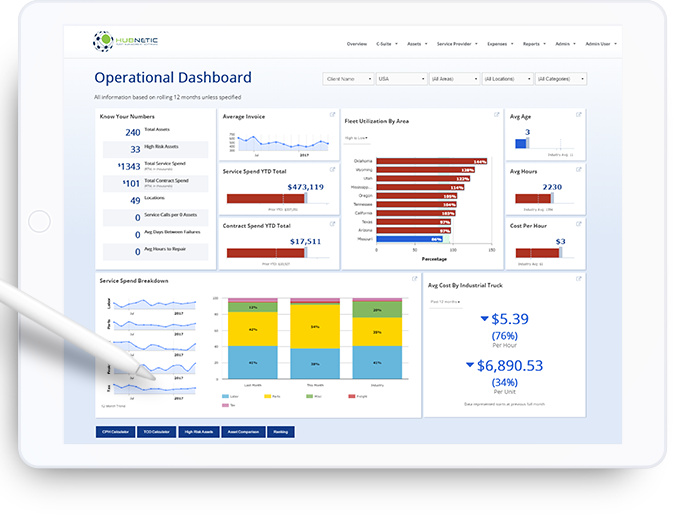

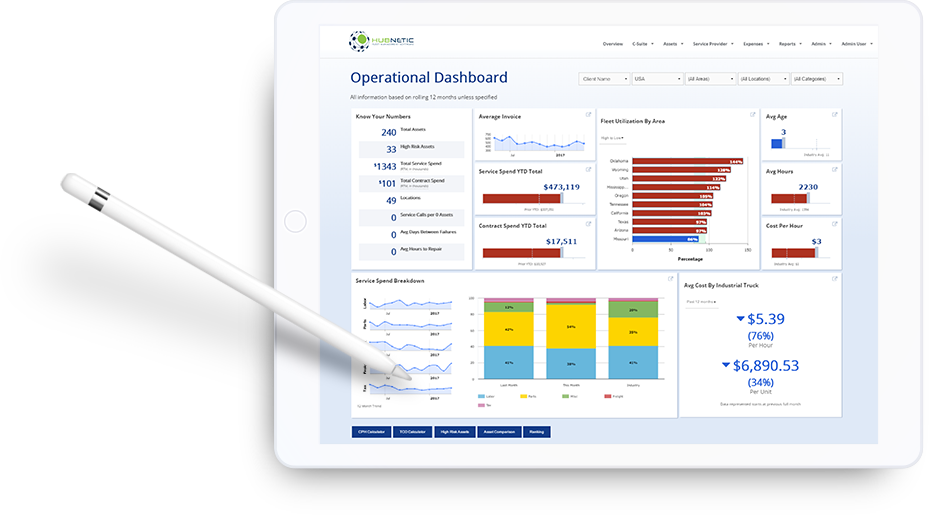

We found that most fleet management solutions inundated your team with plenty of data, but provided very little guidance on how to use it to improve your fleet's performance. We developed HubNetic to provide you with Actionable Data that benchmarks your results, compares performance and scores service providers so you can make decisions that will Move the Needle.

Above: Sample of C-Suite Overview Page

Above: Sample of C-Suite Overview Page